Industry Application

Provide customers with professional case solutions

Overhead crane is a kind of bridge type crane with bridge running on elevated track, commonly known as overhead crane, which is widely used in indoor and outdoor warehouses, workshops, wharfs and open storage yards. Ordinary bridge cranes are generally composed of a hoisting trolley, a bridge operating mechanism, and a bridge metal structure. The hoisting trolley is composed of three parts: the hoisting mechanism, the trolley running mechanism and the trolley frame.

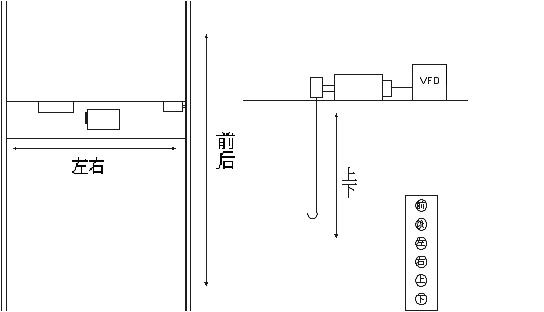

The crane operating mechanism generally only uses four active and driven wheels. If the lifting capacity is large, the method of increasing the wheels is often used to reduce the wheel pressure. When there are more than four wheels, an articulated balanced frame device must be used to distribute the load of the crane evenly on each wheel. Its operating mechanism consists of three basically independent drag systems:

The electric running mechanism consists of three basically independent drag systems.

② Cart dragging system: drag the whole crane to make a "horizontal" movement along the workshop (subject to the operator's sitting direction).

③ Trolley dragging system: drag the hook and heavy objects to make a "longitudinal" movement along the bridge.

④ Hook drag system: drag the heavy object to make the up and down movement of lifting or lowering.

Overhead cranes have relatively low control requirements for frequency converters in cart dragging and trolley dragging, while the hook drag system has the characteristics of large inertia and four-quadrant operation due to the operation of the hoisting mechanism. Compared with other transmission machinery, There are more stringent safety and performance requirements for inverters.

1. On-site technical requirements for frequency conversion ① The functions of soft start and soft stop reduce the impact of mechanical transmission; ② has a fast dynamic response; ③ It can meet the operation of frequent starting, braking, forward and reverse rotation under heavy load.

2. Application effect Provide SVC control mode: Huixunjun H300 series inverter provides SVC control mode, which can obtain the performance close to closed-loop control, and can well meet the full load (even overload, usually running time is very short) when starting the lifting equipment. )run. At the same time, the speed sensor is omitted, and the maintenance cost is low.

3. Frequency converter debugging parameters P4.05=0 P4.01=2 (The function of connection port D12 is selected as reverse) P0.02=1 (running command channel) P9.03=0 (overvoltage speed gain) P9.04=120 (stall protection voltage) P0.17=3 (acceleration time) P0.18=3 (deceleration time) P1.05=1380 (rated motor speed) | 4. On-site pictures

|

Through frequency conversion technology, not only the safe operation time of bridge cranes is improved, but also the labor maintenance intensity is greatly reduced. Therefore, the application of frequency conversion speed regulation technology in bridge cranes is worth popularizing.