Industry Application

Provide customers with professional case solutions

Forging machinery is one of the important components of industrial basic equipment. Stamping equipment is a major member of the forging machinery family and is widely used in important industrial sectors such as aerospace, automobile manufacturing, transportation, metallurgy and chemical industry. In any industrially developed country, the technical level and possession of its stamping equipment are an important symbol of its industrial development level.

A punch is a stamping press, so it is also called a press. Through the application of various molds, products that cannot be achieved by traditional machining can be made. Stamping production is mainly for sheets. Through the die, the sheet can be punched, formed, trimmed, fine blanked, shaped and extruded, etc. It is widely used in stamping and forming of electronics, communications, computers, household appliances, furniture, vehicles, hardware parts, etc. . |  |

High precision, reliable operation performance and safety;

Production automation, labor saving and high efficiency;

The sliding adjustment is divided into manual adjustment and electric adjustment, which is convenient, reliable, safe and fast;

The high-rigidity and high-precision frame has been heat-treated to eliminate the internal stress of the fuselage, so that the equipment can work stably for a long time without deformation.

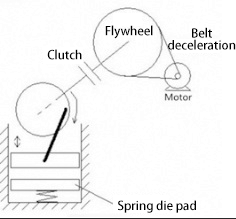

The design principle of the punch press is to convert the circular motion into linear motion, the main motor outputs the power to drive the flywheel, and the high-speed punch drives the gear, crankshaft (or eccentric gear), connecting rod, etc. to operate through the clutch to achieve the linear motion of the slider. The movement from the main motor to the connecting rod is a circular motion. Between the connecting rod of the punch press and the slider, there needs to be a transition point for circular motion and linear motion. There are roughly two mechanisms in its design, one is a ball type, and the other is a pin type (cylindrical type). The motion is converted into linear motion of the slider. |  |

1. Wiring ①Input (main power) R S T , output (motor) U V W ②Start signal DI1 forward rotation DI2 reverse rotation COM common terminal ③Fault contact TC1 TB1 ④Frequency given AI1 10V GND ⑤FM COM pulse reception ⑥D(zhuǎn)O1 GND Motor alarm ⑦ GND and COM are shorted, DI5 is shorted with FM | 2. Inverter built-in parameters

|

3. On-site renderings

| |

The use of Huixunjun H500 inverter to achieve stable and reliable operation has won good economic benefits for the enterprise. Its advantages are mainly reflected in the following points:

1. Real current vector control technology, low frequency torque.

2. Fast and stable speed tracking restart function.

3. Protect the current limiting function of the inverter and the motor.

4. Good voltage suppression function.