Industry Application

Provide customers with professional case solutions

Fully automatic industrial washing machine refers to a large-capacity washing machine that has functions such as initial washing, washing, rinsing, bleaching and dehydration, and can realize automatic conversion without manual operation between functions. The washing machine can be divided into three types: suspension vibration isolation type, water injection balance vibration isolation type, and gravity fixed type according to different methods of vibration reduction and vibration isolation. At present, the mainstream products on the market are suspension vibration isolation automatic industrial washing machines. It is mainly composed of shell, frame panel, inner drum of main shaft, transmission system, anti-vibration system, front door parts, feeding parts, braking parts, water discharge valve parts, ultra-vibration parts, control parts, pipeline parts and pneumatic system.

The industrial washing machine is driven by the motor to rotate the inner tank through the belt variable speed, and rotates forward and reverse under the action of the frequency converter, which drives the water and the clothes to move asynchronously, so that the water and the clothes are rubbed and rubbed against each other to achieve the purpose of washing.

Industrial washing machines are the most common, simplest, and easiest to maintain washing equipment. Compact structure, convenient operation and maintenance, reasonable design, stable operation and long service life. It has the advantages of high washing efficiency, small footprint, beautiful appearance, excellent performance and durability.

It is suitable for washing all kinds of cotton, wool, hemp, chemical fiber blended and other clothing fabrics. It is widely used in laundry rooms such as garment factories, washing factories, industrial and mining enterprises, schools, hotels, hotels, and hospitals.

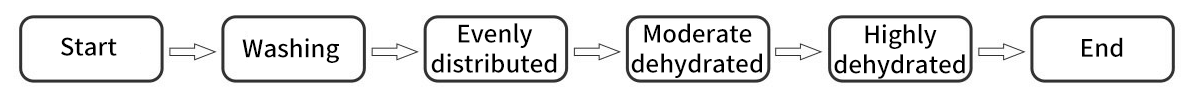

H500 series can match the corresponding power three-phase asynchronous motor. Through its multi-speed function, it can realize uniform water intake, washing (forward and reverse); accelerated drainage; high-speed dehydration and other laundry processes, please refer to the following wiring and parameter descriptions for details.

1. Premise

After the inverter and motor parameters are tuned, the following operations can be performed

2. Terminal wiring

3. Parameter setting

4. Frequency setting

| 5. On-site pictures

|

In recent years, industrial washing equipment is mainly based on water washing equipment. The application of frequency converters has become more and more popular. Therefore, frequency converters have brought a new technological revolution to industrial washing equipment, from the earliest non-speed-adjustable semi-automatic washing machines to Two two-speed motors to achieve a four-speed fully automatic washer. Huixunjun H500 series inverters have excellent performance, reliable quality, high cost performance, simple adjustment and convenient operation. Especially for the technical requirements of industrial washing machines, the V/F curve self-adjustment technology is adopted to automatically diagnose and adjust V/F according to the washing conditions. The curve makes the washing machine start smoothly, the current is reduced, and the operation is stable during the customer's use, which has been well received by the users.